M 248Sewing machine for reinforcing composite materials with carbon fibre threads

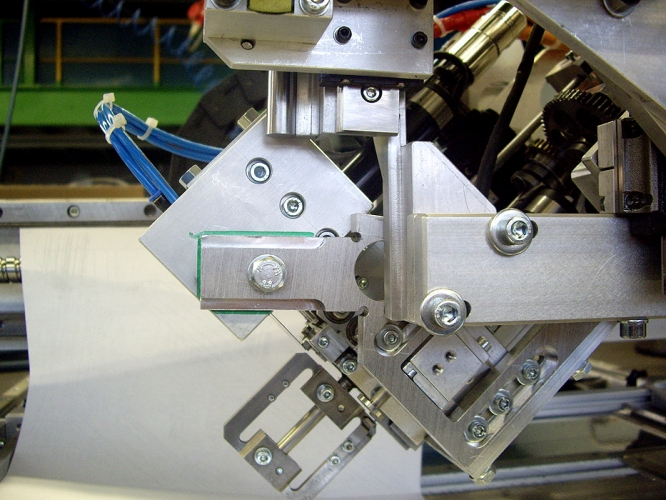

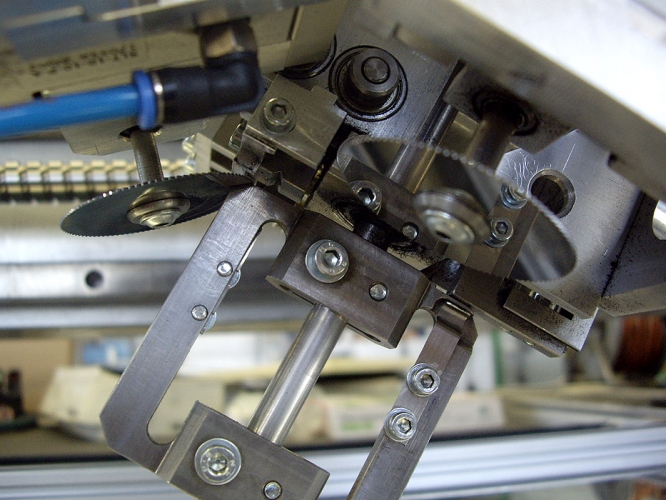

The procedure involves a needle in the form of a hook first penetrating the foam, then picking up the fibre bundle on the underside and pulling it up. As the fibres and the needle do not pass through the hole at the same time, they come up one after the other, it is possible, depending on the diameter of the needle and the form of the hook, to determine the size of the hole according to the thickness of the roving (thread).

This procedure ensures the ideal ratio of resin to fibre, so that in the end product, after the infusion, it is principally the newly introduced fibres which are responsible for the improvement in the mechanical qualities of the basic foam material.

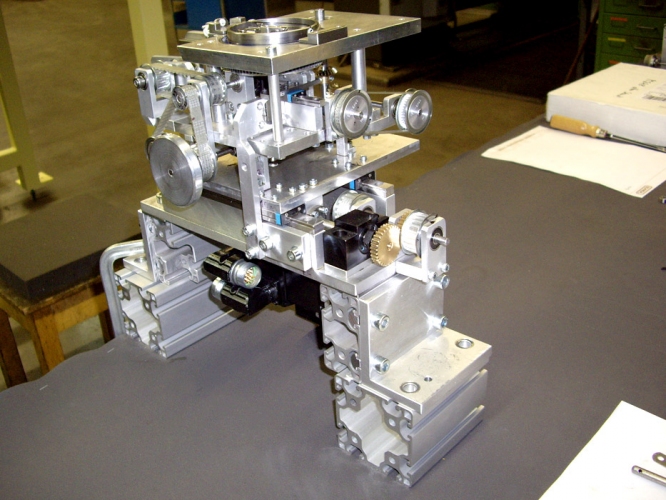

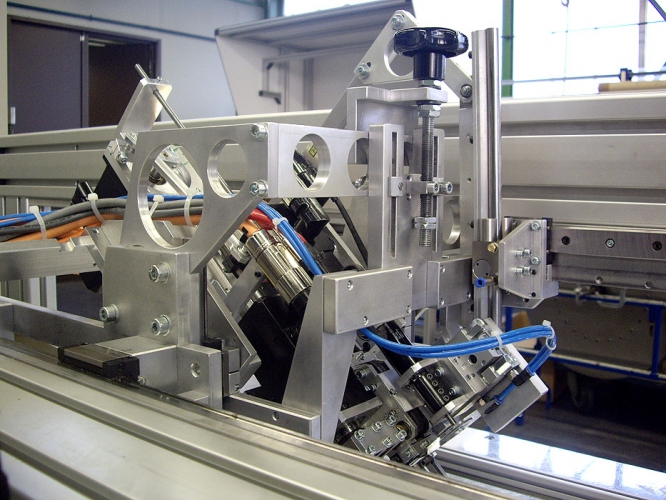

A sewing machine portal has been constructed into which the newly developed sewing procedure has been integrated.

- Stitch angles: 90°, 75°, 60°, 45° (manually adjustable)

- Stitch speed: 10 Hz at a substrate height of 5 mm

- Tolerances: +/- 0.1 mm

- Plate rotation: 360° in 1° steps (automatic)

- Substrates: hard foam 51kg/m³ or lower

- Substrate qualities: Foam plates 500 x 500 mm, foam thickness 5-30 mm

- Semi-finished reinforcement : carbon fibre roving