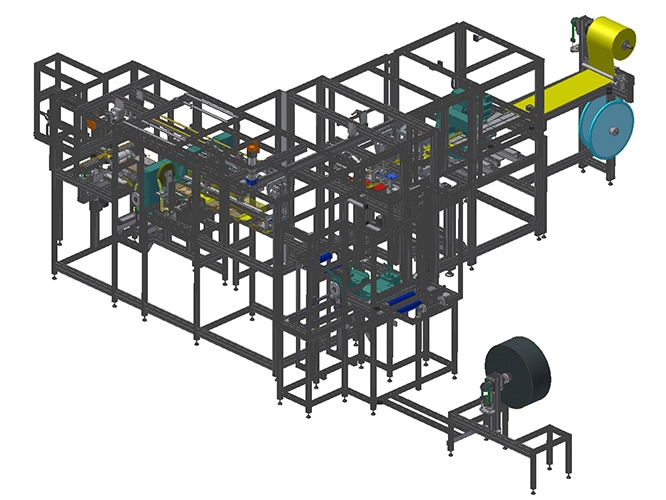

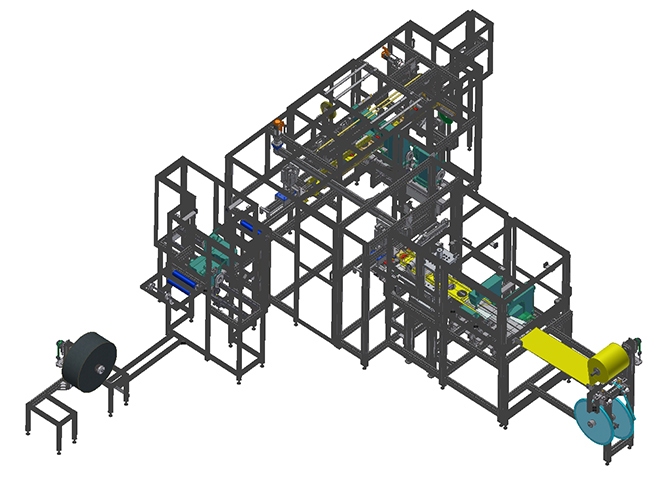

M 277 Fully automatic assembly line for floor cleaning cloths

The floor cleaning cloths (mop) are produced on an automatic assembly line. This unit is modular so that various extensions and optional functions can be ordered to add to the existing parts at any time.

TECHNICAL DATA

- Basic machine body: aluminium assembly profile (item)

- Cycle time: approx. 4-5 parts/min, depending on the length of the piece

Manufacturing the pockets (module 1):

The printed pocket material and the crosspiece material (on rolls) are brought together by an inlet ferrule and the edge flipped over. The two materials are sewn together with a two-needle double chain stitch sewing machine. Next to the sewing machine there is the round blade which cuts the pockets to the precise length required. The feeder transports these sewn pockets to be cut to length and, after that, to be edged. The process is then continued in module two.

Edging and lengthwise sewing station (module 2):

The rolls of mop material are put on a roller dispenser and drawn to the two adjustable edging sewing machines. After this sewing station the sewn pocket (from module 1) is positioned accurately on the mop material and sewn at the edges. This process terminated, the sewn parts are cut precisely to the required length and taken to the stacking unit by a pull-off device or transported on to another sewing station.