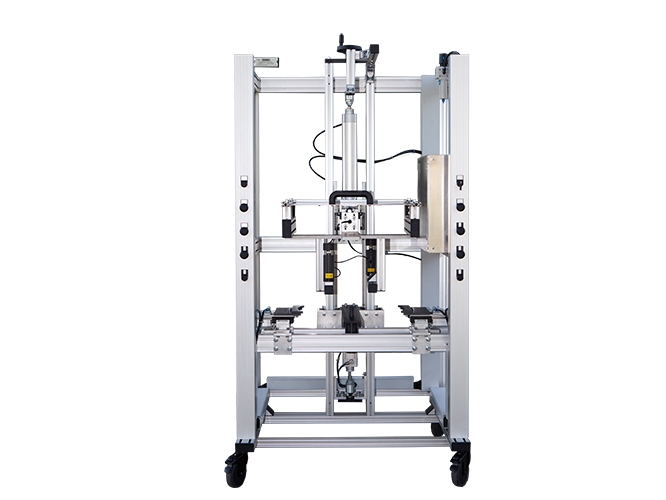

M 275 Assembly unit for tynex brushes

On this machine brushes are produced which can, for example, be used in a cleaning unit for aluminium rims after the casting process.

Up to now these brushes have been manufactured in custom-built prototype machine. As a result of development work on this machine, it was possible to increase the degree of automation and the safety level of the unit.

The base (a synthetic plate) is given a coating of glue and manually inserted into the device. After pneumatic locking, the tufts of bristles make their approach. These tufts of 3 mm in diameter are inserted into the pre-bored holes. When this process is complete a removable tray is put in for the subsequent gluing process. The following 180° turn enables the bristles to rest above the glue-covered base. The tray is now withdrawn and the bristle tufts dip down into the glue.

During the pressing process with 6 bar pressure the brushes can harden. This process takes ten minutes. The press separates out after the drying process and the completed brush can be removed.